A recent post on LinkedIn suggested that contractors should use their “common sense” and just get on with it, rather than referring back to the structural engineer when something on site doesn’t match the drawings.

On the surface, it sounds practical. After all, contractors are on site every day, they know the building, and they understand how things fit together in reality. But there’s a problem with that line of thinking: common sense can’t calculate load paths.

The reality behind the drawings

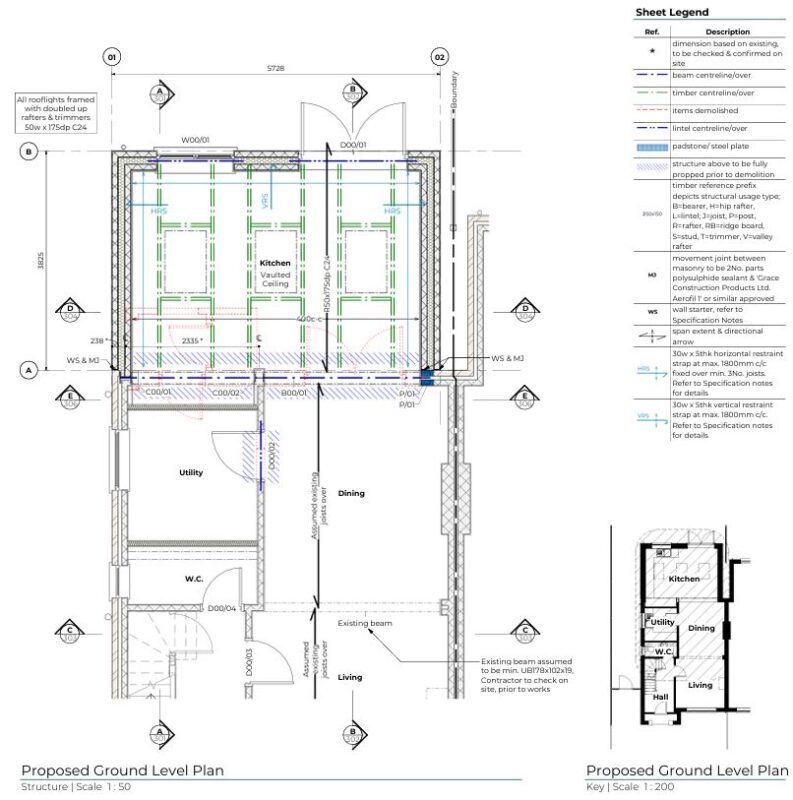

As structural engineers, every design we produce is based on assumptions.

For example, when walls are removed, we may assume that an existing steel beam lies hidden behind plasterboard. We can’t always know what that beam was originally designed to carry, but we can calculate exactly what it needs to support going forward.

That’s why our drawings often include notes such as:

“This beam needs to be this size, or equivalent. Contractor to confirm.”

This instruction isn’t vague, it’s deliberate. It means that if the contractor uncovers something different from what we assumed, their next step is to come back to the designer.

Typical internal alterations

Why it matters

To the untrained eye, a beam of similar depth might look “close enough.” But here’s the danger: not all beams are created equal. A 152UC, a 152UB, and a 150-deep channel may look nearly identical, yet their performance can vary significantly.

One section may be prone to lateral torsional buckling, another might lack the stiffness required, and another could be more than adequate. The only way to know for sure is through design calculations. If a contractor relies on “common sense” to make that call, the risk is very real: overloading, hidden weaknesses, and ultimately, potential failure.

Clarity beats assumption

The Building Safety Act is unambiguous: the designer is responsible for the design. Contractors aren’t expected to carry that responsibility and shouldn’t have to.

The correct process is clear:

- Engineers make their assumptions explicit.

- Contractors confirm conditions on site.

- Any discrepancies are referred back to the structural engineer for reassessment.

This isn’t red tape. It’s safety.

A beam isn’t safe simply because it “looks the right depth.”

Shape, section, restraint, and load conditions all play a role.

Contractors bring enormous value through their skill and experience on site. But they should never be left to make structural design decisions in isolation.

Common sense has its place, but when it comes to structural safety, clarity and collaboration will always beat assumption.