You’re reviewing the structural design package and your heart sinks.

- Massive beams

- Thick slabs

- Steel reinforcement that makes your QS twitch

You find yourself asking: “Is all this really necessary, or is my engineer just playing it safe?”

It’s a common frustration especially when the numbers don’t seem to add up with the rest of your project goals. Over-engineering isn’t usually about engineers being cautious or lazy. It’s often the direct result of when we’re brought into the design process.

Timing is Everything

By the time many structural engineers are asked to get involved, key architectural decisions are already locked in.

- Load paths have been compromised,

- floor-to-floor heights are fixed, and

- grid spacing is rigid

With these constraints in place, we’re left with limited room to manoeuvre so we compensate with extra structure.

- Bigger beams

- Thicker slabs

- Heavier reinforcement

We’re not trying to be difficult. We’re just trying to keep your building safe and compliant—with the options available to us. And often, those options are far from ideal.

This is how over-engineering creeps in. Not from negligence, but from necessity. Because late involvement equals fewer choices. And fewer choices mean we design conservatively, building in larger safety margins to protect what matters most.

What Happens When You Involve Us Early?

Flip the timeline, and everything changes.

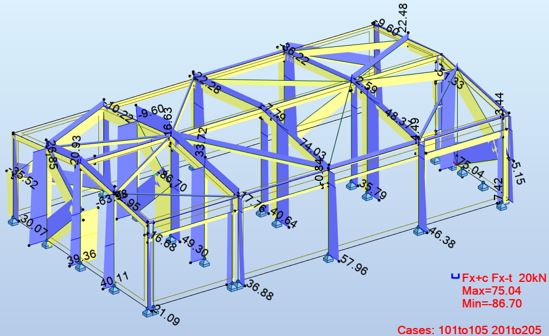

When we’re brought in early, alongside the architect, QS, and services engineer we can help shape the structure from day one. That doesn’t just mean safety; it means efficiency.

We’ve helped developers:

- Cut steel tonnage by up to 20% simply through better coordination of services and structural zones

- Avoid deep foundations by subtly adjusting column layouts to optimise loads

- Retain and reuse existing buildings that others would have written off, saving both money and time

In one recent project, early collaboration allowed us to eliminate an entire transfer structure by influencing the initial layout. That alone shaved weeks off the programme and hundreds of thousands from the budget.

Lean Design Is Collaborative Design

Contrary to the myth, most engineers don’t want to over-engineer.

We want to design elegant, efficient structures that perform beautifully and build easily. But we need the opportunity to do that which means being at the table before the big decisions are made.

Over-engineering isn’t hardwired into our mindset, it’s hardwired into a process that brings us in too late.

So if your structural design feels oversized or your costs are ballooning, don’t jump to blame the engineer. Instead, look at the timeline.

Design Smarter, Not Heavier

Great structural design isn’t about adding more it’s about knowing what you can take away.

But that kind of precision comes from early involvement, not late fixes.

If you’re looking to build leaner, faster, and smarter, the solution isn’t finding a new engineer.

It’s involving the right one at the right time.